Kunshan Shuojing Photoelectric Technology Co., LTD

Mr. Jiang:18261685858

Mr. Jiang:13482461082

Email:gingerjzj@163.com

Adress:Room 809, Building 2, Jiayu International Business Plaza, Zhoushi Town, Kunshan City

Web address:shuojingcrystal.com

Application of sapphire crystal in industrial field (2)

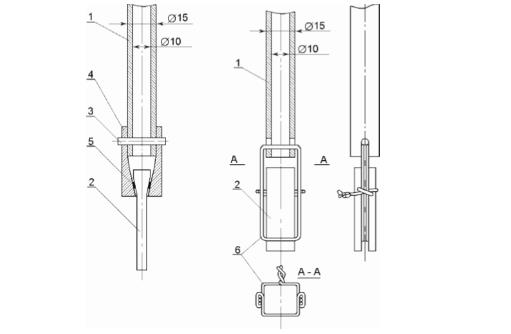

Sapphire structural elements are used in the growth of other crystals. Fig. 1.2 [8] shows the method of seed fixation during the growth of large size BGO crystals. Using this device reduces platinum consumption and increases longevity. When using the heater moving method to grow high-temperature crystals, the high thermal conductivity of sapphire is used, and a large piece of sapphire is used as a crucible support fixed on a water-cooled rod to facilitate heat dissipation from the bottom of the crucible [9].

Sapphire substrate is one of the most important structural materials of this material. It is used for epitaxial growth of semiconductor thin films like Si, GaN, AIGaN, and for the manufacture of integrated circuits. Sapphire substrates are inert, work at high temperatures and mechanical loads, and can achieve large dimensions. Therefore, they are even used where the lattice constants and the parameters of the hetero-epitaxial structure do not exactly match.

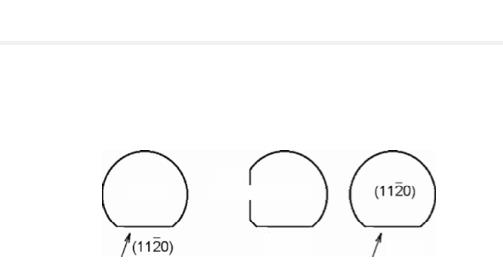

For ease of positioning, the substrate is equipped with one or two additional (marked) sides (Fig. 1.3). C-planes are used for CdS, CdTe, CdSe, GaN, SiC, InAlGaN, and LiNbO3 coatings for sapphire, and for epitaxial growth of certain oxides (eg ZnO) and metal thin films. A-plane is a coating of cobalt and iron used to make hybrid microcircuits, devices with high temperature superconductivity, and crystals.

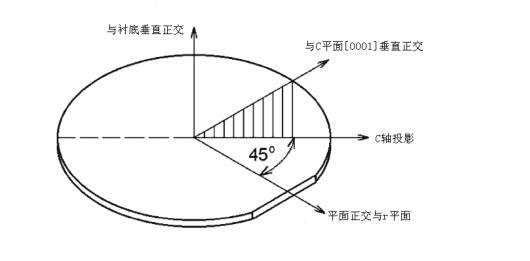

The W(110), Au(111) and V(011).R planes are suitable for MgO, a-ZnO, and Si-coated sapphire by heteroepitaxy (Fig. 1.4). However, when MnO was coated on the inner layer, other planes were also coated.

(0001)Sapphire/(111)spine/(111)mgo

(2 ii0) sapphire/(111)spine/(111)mgo

While making the "Silicon Coated Sapphire" construction. N-type silicon is coated directly onto the R(1012) plane of sapphire or through a buffer layer. The electronic barrier (potential barrier) between homing and sapphire is 3.25eV. This layer was heated from a sublimated silicon source to 1,650K and deposited onto sapphire, with a substrate temperature of 720-1020K. At low temperatures, the method of growing layers is [110]; when the temperature is greater than 820K, they are oriented in the [100] direction. At 820K, a binary orientation occurs: silicon.

(100), (110) [10].

Figure 1.2 Seed crystal fixture: (1) Sapphire tube, (2) Seed crystal, (3) Sapphire rod, (4) Corundum cone, (5) Platinum backing, (6)Platinum wire

Figure 1.3 Relative positions of base and additional planes

Figure 1.4 Illustration of a (100) silicon film on the r-plane of sapphire

ZnO with wurtzite structure was crystallized using (1120)7.0 / (0112) sapphire and (0001)zno/(01 1 1) sapphire. Sapphire substrates are used in pressure, mass and humidity sensors, as well as 1R radiation detection

(HgCdTe film on sapphire) and other devices.

Josephson transitions are created in high-temperature superconducting films using a bicrystalline substrate. Doublet ribbons grow on double crystal seeds. The orientation of the broad plane is [1102] and the growth direction of the crystal is [1102]. The angle of the twin crystals is 2 X14° [10]. The production of laser diodes and ultra-bright blue and green light-emitting diodes (LEDs) is in rapid development. Equally fast-growing are their fields of application - from traffic lights to the treatment of Alzheimer's patients (with an experimental device incorporating blue light-emitting diodes emitting 30 lux of light to stimulate to reduce disturbances in the sleep and wake cycles). degree), apparently due to lowering the body temperature of the patient [11]. The blue light-emitting diodes use heterostructured GaN/sapphire (albeit with a 13% lattice mismatch) and GaN/InGaN/GaN/(0001) sapphire.

The following orientation relationships are achieved in the nitride-sapphire device:

(0001) Al1,1/( 000 1 ) Sapphire

(0001) Gad/(0001) Sapphire

(1120)AiN/(1012)Sapphire

(1120)GaN/(1012)Sapphire

( 126) A1N/(1012) Sapphire

Among other conditions, the concentrations of phases (1126) and (1120) are affected by substrate disorientation.

The concentration of carriers (holes) in the GaN layer reaches 1016-1018 cm-3. The substrates currently used are up to 2,3,4 inches in diameter. The allowable deviation of the substrate on the plane is is (0001) ± 0.1°.

Blue light diodes are used as the basis for making white light sources to replace incandescent and fluorescent lamps. These new light sources are more economical light sources; they last dozens of times longer. The output of high quantum radiation is close to 100 % in the blue and green regions of the spectrum, enabling light-emitting diodes to be used in information displays, mobile devices, signaling devices and other devices.

Among the promising trends in the use of sapphire substrates, it is worth mentioning the technology of growing carbon nanotubes on sapphire. This is an approach being developed at the University of Northern California. This new material seems promising for nanometer transistors and sensors. Researchers have found that the surface of a flat sapphire instinctively arranges single-walled carbon nanotubes into a useful pattern. There is no boilerplate to provide guidance to generate this structure, it is formed automatically.

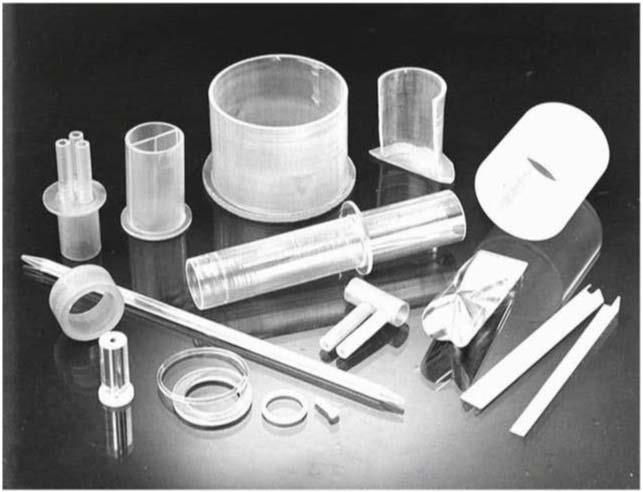

Chemical vessels such as crucibles, boats, measuring cups, reactors, and other items (Figure 1.5) have been used since the development of methods for shaped sapphire growth. Due to its high corrosion resistance (see chapter 2.2), these products can be used when high purity substances are to be obtained, since in this process even the smallest chemical container materials used are not allowed to be mixed into them . They can also be used for the dispersion of hard materials. Grinding sapphire tools such as pulverizers, abrasives (spherical, cylindrical), mortars, and rods are also produced.

Figure 1.5 Chemical vessel made of sapphire

The rectangular sapphire cuvette used in the thermal fluoride melting spectroscopy test cannot be replaced by any other container.

Sapphire capillaries are used in research on microbursts, twin crystal growth, microdosimetry devices, and other applications. In recent years of technological process research in this field, the diameter of capillary channels in the as-grown state has been reduced from 1 mm to 0.4 mm.

Sapphire fibers are used to create synthetic materials, strengthening metal and ceramic composites. The main requirements for these fibers are high strength and reasonable price. Fiber growth of the composite, the diameter of which is 0.4-0.7mm. Their lengths vary about 10 times their diameter. A coating of SiC0.9900.01 with a thickness of 4–6 gm can provide the strength of the fibers (Fig. 1.6) [12]. Naturally, the strength properties of fibers used in composites can be altered by interaction with the matrix. This change is characteristic of the thermal stability of nickel-based compositions.

In addition to fibers for composites, sapphire whiskers in the 1–10 gm diameter class have also been grown. At temperatures up to 1,270K, these whiskers are stronger than most crystals. From room temperature to 1870K, the average strength of the whiskers decreased from 950 kg/mm2 to 150 kg/mm2. Reinforcement with sapphire whiskers increases the strength of the aluminum matrix by as much as 5 times; at 0.9T of the matrix, the composite retains considerable strength. The composite composed of aluminum powder (83.7%), silicon powder (6.3%) and sapphire whisker (10%) was pressed at 810K, and its ultimate strength could reach 67.5 kg mm2 (without whiskers, the ultimate strength was 67.5 kg mm2). The strength is 33.5 kg/mm2). Sapphire whiskers can also be used to make insulating pads with a density of 0.02 g/cm3 for high temperatures of 2,270 K.

Sapphire abrasive (a‐Al203) grain is a very sharp grinding, durable blasting abrasive that can be recycled many times. Because of its price and longevity and hardness, this particle is widely used for blast finishing and surface treatment. It is harder than other commonly used sandblasting materials, alumina particles, and can even penetrate and cut the hardest metals and carbides.

About 50% lighter than metallic media, with twice as many particles per pound of alumina. Fast cutting minimizes the risk of cutting thin materials by eliminating the surface stress caused by heavy, slow cutting media.

Alumina has a wide range of applications, from cleaning engine heads, valves, pistons and turbine blades in the aerospace industry to engraving and marking on steles. It is also frequently used for precision finishing of tinplate surfaces, as well as for cleaning and processing metal sprayed, plated and soldered parts. The larger the grit size, the faster it will cut, but taking into account the size of the perforations and holes, the grit must be able to pass through the holes of the screen when the media is to be separated from the part after use. Standard mesh sizes for brown alumina are 12/36/60/80/120/220; standard mesh sizes for white alumina are 36/60/80/100/120/220/240.

Dispersed rigid composites are composed of a matrix (eg aluminum or nickel) into which particles of high melting point and high strength elements (eg corundum particles) are incorporated. Introduced into an aluminum or nickel matrix, the quantity of finely dispersed corundum particles is typically 2.5-10% by mass. CD discs are made of polycarbonate. In the author's opinion, in the near future, sapphire discs will be developed for long-term storage of important information. Spherical lenses are the best tool for improving signal coupling between fibers, transmitters and detectors. Polished sapphire or ruby will be made into spheres of diameter D=0.3-6.3 5 mm ± 2.54 μm, within 0.64 μm of steradian.

Kunshan Shuojing Optoelectronics Technology Co., Ltd. is involved in a wide range of new materials, and has complete preparation methods and means for functional ceramics and sapphire crystals, scintillation crystals, and laser crystals, forming optically transparent ceramics, sapphire optical windows, scintillation crystals, lasers and nonlinear crystals The main four series of high-tech products.